For carrying up a ladder i set it long side down put a c clamp tightly on the upper edge near the center and lift it behind me while i climb.

Moving multiple sheets of plywood up and down steps.

Park it with the 2x4 facing away from the saw and attach the rope to the screw eye.

If you look carefully in the photo about a third of the way down the stairs there is a 2 x 6 lying between the tracks.

The convex or humped side should face up and the side you sprayed with water should face down.

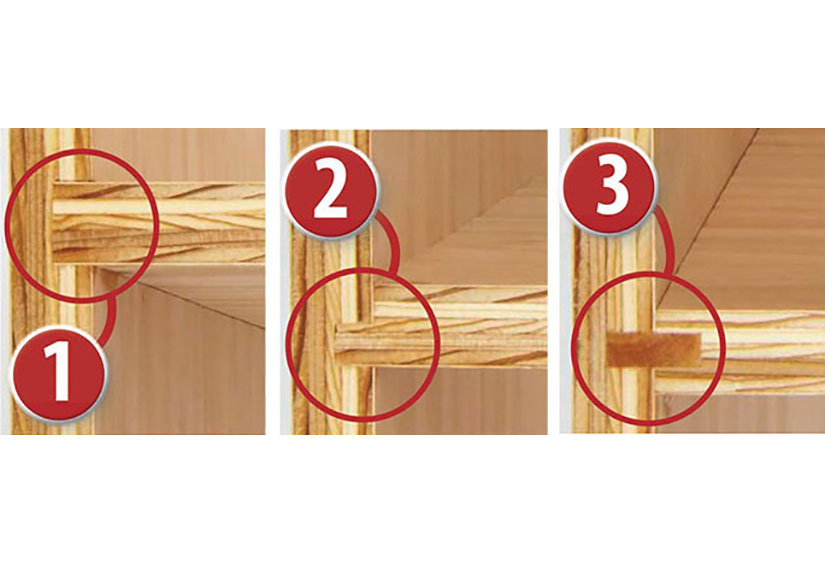

The long segment and short segment of track were tied together on the steps using the ends of the tracks bound with plywood.

It also avoids errant plywood corners from damaging newly installed wallboard in the stairwell.

This 2 x 6 is bolted using wing nuts to the two crossing sheets of plywood.

Once you have made your cuts lay down the plywood sheets the way you want them as a test.

Once glued set the plywood on the subfloor and nail it down.

Moisture can seep up through the earth causing your plywood to rot.

Space your lumber about 2 feet 0 61 m apart to ensure it s.

Grip the edges backhand somewhere below the centerline.

Drop a line with a tension hook grab the sheet and pull it up the inclined ladder.

To protect your plywood sheets from warping the best way to store them is by laying them flat step 2 use lumber to create a base that will keep the plywood off the ground.

Rollers that move individually make it easy to pull heavy sheets of plywood and mdf in and out without disturbing the other sheets.

This works well for moving 5 or 10 sheets quickly.

Set the plywood sheet on a flat surface that has adequate exposure to warm air such as a paved driveway on a warm sunny day.

If everything looks right you are ready to attach the plywood to the subfloor.

For moving plywood on the ground i stand the sheet up on the short end.

In my search results i found articles telling me to spread dishwasher detergent on the floor to decrease friction use moving blankets and drag the item up the stairs create a pulley contraption at the top of the stairs and slide it over a diy plywood ramp and all sorts of other tips that didn t seem practical for our situation.

But for those first few years i was really only using the track saw to break down sheets of plywood into their rough parts which i would then run through the tablesaw for final sizing.

No more trying to shove full sheets of plywood through a small job site tablesaw.

When i got my first track saw years ago it was an absolute game changer for my trim carpentry work.

Secure it at the top with the turnbutton and roll the plywood and dolly to the saw.

Step 1 section off a 4 by 8 ft 1 2 by 2 4 m section of your garage floor.

Put my back against it.

Now slide the sheet of plywood into the dolly.

Vote for me in the woodworking and full spectrum laser contest if you like my instructable.

I was inspired to make this by a tip from from american woodworker magazine and made it for my small storage space at techshop san francisco.