Molybdenum is a refractory metal that is commonly used as high temperature corrosion resistant metal that can withstand high stress high temperature ranges without greatly softening or expanding.

Molybdenum sheet metal.

The molybdenum sheet needs to be cold rolled under a low rolling reduction and consequently become easier to deform in further working processes.

Our experience and state of the art equipment our experience and state of the art equipment mean that we can get the very most out of our metals.

The molybdenum sheet with the typical thickness from 0 3 mm to 4 mm is rolled by the cold rolling of a 6 rolls reversible mill.

Elmet offers a wide range of cold rolled sheet product in varying thickness and length and per customer request.

First of all compress molybdenum powder into plate shape with isostatic pressing technology sinter under high heat to make the production into molybdenum slab and then roll.

However there are some ways that molybdenum differs from medium hard cast iron or cold rolled steel.

Sheets made of molybdenum and its alloys can be ordered directly in our online shop.

When heated to decomposition molybdenum may emit toxic metal oxide fumes.

Molybdenum is used for its extremely high melting point and relative flexibility.

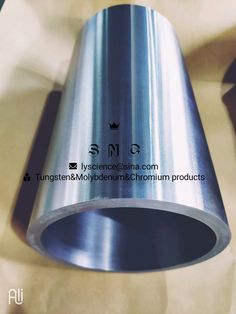

Molybdenum metal is available as disc granules ingot pellets pieces powder rod wire sputtering target and in numerous other forms and custom shapes.

Flammable in the form of dust or powder below 9 microns which may ignite during intensive mechanical treatment.

Our company produce molybdenum sheet by powder metallurgy process.

As with all of our materials our sheet begins as metal powder is pressed into ingots sintered and then rolled.

Molybdenum has a melting point of 2 623 c.

Our talented team is made up of chemists metallurgists and experts from other fields.

Unusual fire and explosion hazards.

Molybdenum metal can be machined with conventional tools and equipment.

May have a violent reaction with oxidizing agents.

They will serve our customers with their excellent skills and professional experiences.

It has a tendency to break out on the edges when cutting tools become dull it is very abrasive.

There you also find an overview of all available sheet dimensions and qualities.